Wire EDM (electrical discharge machining) is a process that uses electrical sparks to cut or shape metal parts in industrial machining applications. It is a highly accurate and efficient method of producing intricate shapes and designs with minimal material loss.

The use of wire EDM services for industrial machining offers many advantages, including greater precision, speed, and cost-effectiveness. With its range of capabilities, wire EDM provides an ideal solution for many types of production needs.

In this article, we will explore the various benefits that wire EDM services can offer for industrial machining operations.

Introduction to Wire EDM Services

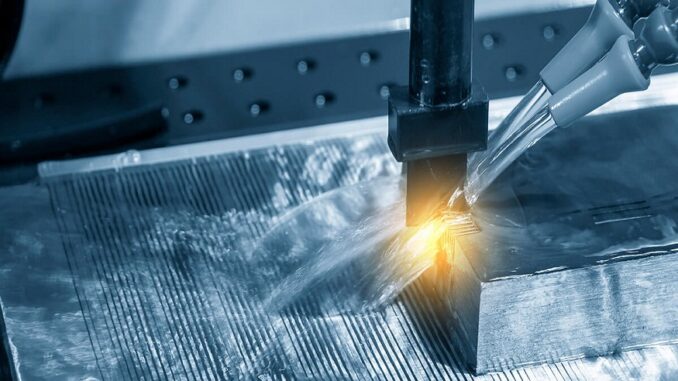

Wire EDM (electrical discharge machining) is a process that uses electrical sparks to cut or shape metal parts in industrial machining applications.

It involves the use of a wire-shaped electrode, which is fed through the material being worked on, and an electric current is used to produce sparks between the electrode and the workpiece. This process is capable of producing intricate shapes with high accuracy and minimal material loss.

Additionally, because this method does not require direct contact between the tool and part, it can be used for components made from hard materials such as stainless steel and titanium without fear of damage or distortion.

In comparison to traditional cutting methods, wire EDM services offer greater precision, speed, and cost-effectiveness. As a result, wire EDM is quickly becoming the go-to solution for many industrial machining applications.

By harnessing the capabilities of wire EDM, businesses can gain a competitive edge in their production processes.

Advantages of Wire EDM for Industrial Machining

Wire EDM services offer many advantages when it comes to industrial machining operations. Here are some of the benefits that this process provides:

Precision and Accuracy

With its ability to produce intricate shapes with high accuracy and minimal material loss, wire EDM offers unparalleled precision and accuracy when compared to traditional cutting methods. This makes it an ideal choice for producing complex parts with tolerances as low as 0.001 inches (0.025 mm).

Speed of Production

Wire EDM services can complete operations quickly, allowing businesses to increase their production speed and output. Additionally, the lack of direct contact between the tool and part reduces wear on the tools, which lengthens their lifespan and further increases production efficiency.

Cost-Effectiveness

In addition to its accuracy and speed benefits, wire EDM is also more cost-effective than traditional cutting methods due to its lower material costs and reduced need for replacement tools. This makes it an attractive solution for businesses looking to reduce their production expenses while still maintaining high quality standards.

Conclusion

Wire EDM services offer many benefits for industrial machining operations, including precision and accuracy, speed of production, and cost-effectiveness. As a result, wire EDM is quickly becoming the go-to solution for many businesses in need of a reliable and cost-effective method for producing intricate parts with minimal material loss.

By harnessing the capabilities of wire EDM services, businesses can gain a competitive edge in their production processes.

Leave a Reply

You must be logged in to post a comment.