Flow dividers are critical components in hydraulic systems, ensuring precise and balanced distribution of fluid across multiple actuators. They are widely used in industrial machinery, agricultural equipment, and mobile hydraulics to synchronize motion and optimize system efficiency. Like all hydraulic components, the lifespan of flow dividers depends heavily on proper maintenance and operational care.

This guide provides actionable maintenance tips to extend the life of flow dividers while ensuring the consistent performance of your hydraulic systems. It also highlights how the maintenance of related components, such as high-pressure gear pumps, plays a role in the overall efficiency and durability of the system.

Understanding Flow Dividers

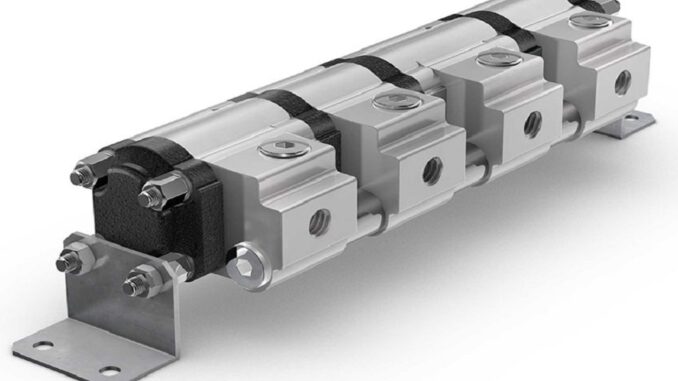

Flow dividers are hydraulic devices designed to split a single flow of fluid into two or more proportional outputs. They maintain synchronization between hydraulic actuators, ensuring smooth and coordinated operation. Unlike standard hydraulic components, flow dividers must handle variations in load, pressure, and flow while maintaining precision.

Proper maintenance of flow dividers is essential to prevent wear, leaks, and imbalances that can affect the performance of the entire hydraulic system. Neglecting maintenance can lead to uneven flow distribution, premature wear of hydraulic components, and potential downtime.

High-pressure gear pumps often work in tandem with flow dividers to supply consistent fluid pressure to the system. Ensuring both components are well-maintained improves reliability and minimizes the risk of costly failures.

Key Maintenance Practices for Flow Dividers

1. Regular Inspection

Frequent inspection is the first step in extending the lifespan of flow dividers. Look for signs of wear, leaks, or corrosion. Common indicators that maintenance is required include:

- Uneven actuator movement

- Excessive noise during operation

- Leaks around seals or fittings

- Pressure fluctuations in the hydraulic system

Visual inspections should be combined with operational checks to detect any performance irregularities. Regular monitoring helps identify minor issues before they escalate into major failures.

2. Maintain Hydraulic Fluid Quality

The performance and longevity of flow dividers are closely linked to hydraulic fluid quality. Contaminated or degraded fluid can cause abrasion, corrosion, and seal damage within the flow divider.

- Filter regularly: Ensure filters are clean and replaced according to manufacturer recommendations.

- Check fluid viscosity: Maintain the correct viscosity to prevent excessive wear and maintain efficient flow.

- Monitor contamination levels: Keep an eye on water, dirt, and other contaminants that can affect both flow dividers and high-pressure gear pumps.

Using high-quality hydraulic fluid and adhering to a regular maintenance schedule significantly reduces the risk of internal damage and improves overall system efficiency.

3. Proper Lubrication

Flow dividers with internal moving components require adequate lubrication to prevent wear and maintain smooth operation. Some flow dividers are lubricated by the hydraulic fluid itself, while others may require periodic manual lubrication.

- Check manufacturer guidelines for lubrication intervals and recommended lubricants.

- Ensure that lubrication reaches all moving parts to avoid friction-related damage.

Proper lubrication reduces the likelihood of gear or spool wear and contributes to the smooth operation of high-pressure gear pumps connected to the system.

4 .Monitor Pressure and Flow Conditions

Flow dividers operate best under specified pressure and flow conditions. Operating outside recommended limits can cause premature wear or even failure.

- Avoid excessive pressure: High-pressure spikes can damage internal components and seals.

- Maintain steady flow: Sudden flow changes can create stress on dividers and downstream actuators.

- Check for proper synchronization: Ensure actuators move in unison to prevent uneven load distribution.

High-pressure gear pumps in the system should also be regularly checked, as they influence the pressure and flow consistency required by flow dividers.

5. Seal and Component Replacement

Seals and internal components of flow dividers are subject to wear over time. Proactive replacement prevents leaks, contamination, and performance degradation.

- Inspect seals during routine maintenance and replace any showing wear or damage.

- Check gear teeth, spools, or other internal parts for signs of abrasion or erosion.

- Use compatible replacement parts to maintain system integrity and performance.

Maintaining the health of seals and components ensures the flow divider continues to operate efficiently, protecting other hydraulic equipment from damage.

6. Keep the System Clean

Hydraulic systems are vulnerable to contamination, which can significantly shorten the lifespan of flow dividers. Implementing strict cleanliness practices protects both the flow divider and connected components.

- Clean hoses, fittings, and reservoirs regularly.

- Avoid introducing dirt or debris during fluid top-ups or repairs.

- Ensure hydraulic tanks are properly sealed to prevent airborne contaminants.

Clean systems help prevent internal abrasion, seal wear, and potential failures in high-pressure gear pumps that work alongside flow dividers.

7. Avoid Overloading the System

Excessive loads or operating conditions beyond the design capacity of the flow divider can lead to premature wear.

- Match the flow divider to system requirements based on flow rate, pressure, and actuator synchronization needs.

- Avoid sudden pressure surges or extreme load changes.

- Monitor system performance regularly to detect early signs of overload.

Properly sizing and operating the flow divider reduces stress on internal components and extends its useful life.

8. Schedule Preventive Maintenance

A structured preventive maintenance program ensures that flow dividers and associated hydraulic components remain in optimal condition.

- Develop a schedule for inspection, cleaning, lubrication, and parts replacement.

- Record maintenance activities to track component lifespan and predict replacements.

- Train operators and maintenance personnel on best practices for handling flow dividers and high-pressure gear pumps.

Preventive maintenance reduces downtime, lowers repair costs, and enhances the overall reliability of the hydraulic system.

Additional Tips for Optimizing System Longevity

- Coordinate with Pump Maintenance: Flow dividers rely on a consistent fluid supply from pumps. Maintaining high-pressure gear pumps ensures stable pressure and flow, reducing stress on the flow divider.

- Monitor Operating Temperatures: Excessive heat can degrade hydraulic fluid and damage components. Use temperature monitoring to maintain safe operating conditions.

- Use Compatible Fluids and Materials: Ensure hydraulic fluids and replacement parts are compatible with system components to prevent corrosion, wear, and performance issues.

- Consider System Upgrades: Upgrading to modern flow dividers with enhanced materials or improved designs can reduce maintenance requirements and increase lifespan.

Flow dividers are essential for maintaining precision and efficiency in hydraulic systems. Their longevity depends on proper maintenance practices, including regular inspection, fluid quality management, lubrication, pressure monitoring, and timely component replacement.

High-pressure gear pumps play a complementary role in maintaining stable flow and pressure, emphasizing the importance of a holistic maintenance approach. By implementing these maintenance strategies, industrial operators can extend the lifespan of flow dividers, reduce downtime, and ensure consistent system performance.

A well-maintained hydraulic system not only saves costs but also enhances operational reliability, making proactive maintenance of flow dividers an investment in the long-term efficiency of your industrial operations.

Leave a Reply

You must be logged in to post a comment.